The Critical Compliance Challenge Facing Malaysian F&B Exporters

For Malaysian F&B manufacturers ready to scale globally, the question isn’t whether to automate compliance—it’s how quickly you can make the transition.

Malaysia’s food and beverage industry stands at a pivotal crossroads. With the sector contributing 3.3% to Malaysia’s GDP and projections indicating growth to 3.9% by 2028, export opportunities have never been more promising. The country’s processed food market is projected to grow at a robust 6.4% CAGR from 2025 to 2031, driven by urbanisation and changing consumer preferences.

Yet behind these impressive growth figures lies a sobering reality that keeps F&B CEOs awake at night: the increasingly complex web of international food safety compliance requirements that can make or break export ambitions.

As the CEO of an export-focused Malaysian F&B company employing 50-500 people with revenues between RM10M-RM100M, you’re intimately familiar with this challenge. Your company is part of an industry that employs 234,832 people and generates export revenues reaching RM3.46 billion as of March 2025. But despite this economic significance, the path to international markets remains fraught with compliance obstacles.

The manual HACCP (Hazard Analysis and Critical Control Points) implementation process that has dominated the industry for decades is no longer sustainable. Traditional compliance approaches require 3+ months for initial documentation, consume RM50,000+ in consultant fees, and divert weeks of internal team time from core business activities.

This antiquated system creates a fundamental bottleneck that prevents Malaysian manufacturers from capitalising on global market opportunities.

The problem extends beyond mere inconvenience. Every day spent wrestling with manual compliance processes is a day your competitors—particularly those in countries with more advanced automated systems—gain market share. The Malaysian food processing industry faces mounting pressure to meet international standards like Codex HACCP, FDA FSMA, and EU regulations, each with their own intricate requirements and documentation demands.

The Devastating Cost of Compliance Inaction

1. Market Access Delays and Lost Revenue Opportunities

When compliance documentation takes months to complete, market entry windows close. In the fast-moving global F&B market, a 3-month delay in obtaining necessary certifications can result in missing entire seasonal demand cycles or losing first-mover advantages in emerging markets. Consider the opportunity cost: if your company generates RM50M annually and targets 20% export growth, a compliance-related delay could cost RM10M in lost revenue potential.

2. Escalating Consultant Dependencies

The current manual system creates an unsustainable dependence on external consultants. With consultant fees exceeding RM50,000 for comprehensive HACCP implementation, smaller Malaysian manufacturers find themselves priced out of international markets. This consultant dependency also creates scheduling bottlenecks—you’re at the mercy of their availability and workload, further delaying your market entry plans.

3. Audit Failures and Reputation Damage

Manual compliance systems are inherently error-prone. Research indicates that manual processes can increase human error rates by up to 30%, creating audit vulnerabilities that can result in certification failures, product recalls, and lasting reputation damage. In today’s interconnected global market, a single compliance failure can permanently damage relationships with international distributors and retailers.

4. Competitive Disadvantage Against Automated Rivals

While Malaysian manufacturers struggle with manual processes, competitors in countries with advanced automation infrastructure are achieving up to 70% faster compliance timelines and 35% reduction in food safety incidents through predictive analytics. This efficiency gap translates directly into competitive disadvantage—they can respond to market opportunities faster, offer more competitive pricing due to lower compliance costs, and demonstrate superior food safety track records to international buyers.

5. Limited Scalability for Multi-Market Expansion

Manual compliance systems don’t scale. Each new market requires separate documentation processes, additional consultant engagements, and incremental time investments. As Malaysia’s foodservice market grows toward an estimated USD27.5 billion by 2030 at a 13.26% CAGR, manufacturers using manual systems will find themselves increasingly unable to capitalise on this growth due to compliance bottlenecks.

The auRELIA Solution: Smart Automation for Malaysian Food Safety Excellence

The future of food safety compliance isn’t just digital—it’s intelligently automated. auRELIA’s Smart HACCP Automation platform specifically addresses the unique challenges facing Malaysian F&B manufacturers, transforming compliance from a growth barrier into a competitive advantage.

Smart HACCP Plan Generation

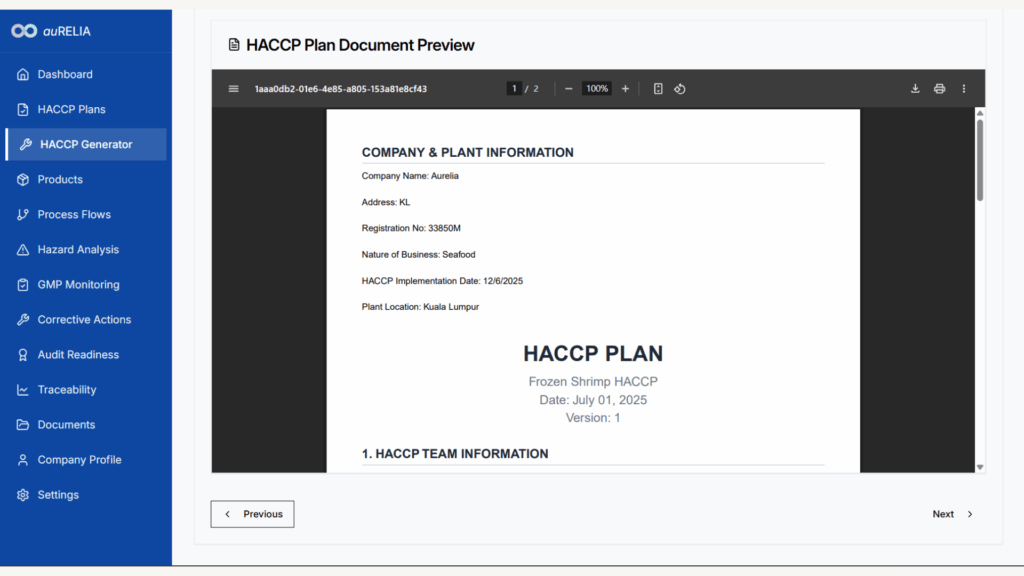

auRELIA’s MVP 1.0 delivers Smart HACCP Plan Generation that produces comprehensive, tailored HACCP plans aligned with both MS1480 and international Codex standards. Our AI-powered system understands the nuances of Malaysian manufacturing processes and generates documentation that meets the specific requirements of your target export markets.

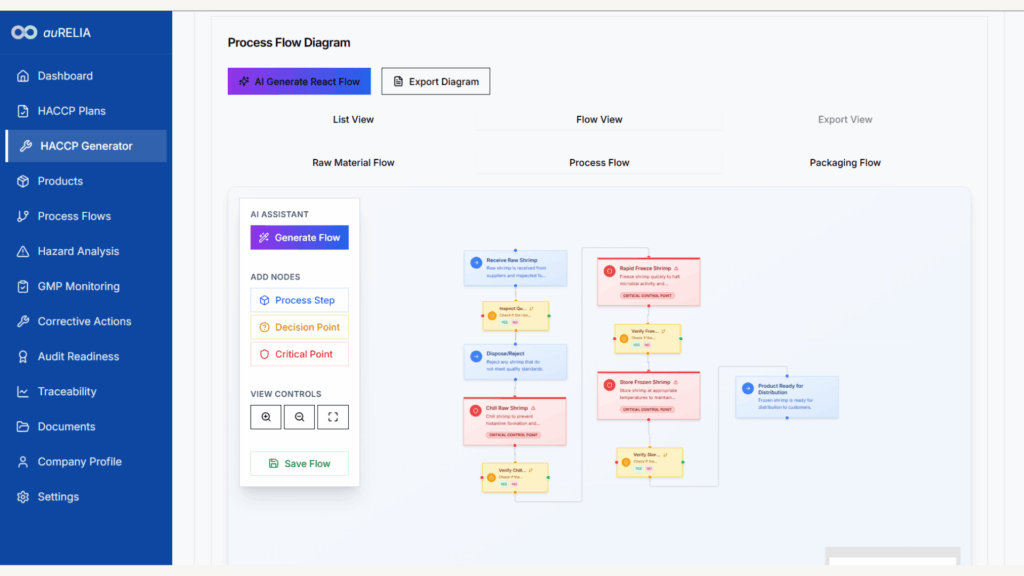

AI-Generated Custom Process Flow Diagrams

Visual documentation is critical for international compliance audits. auRELIA automatically generates custom process flow diagrams specific to your manufacturing operations, ensuring auditors can quickly understand your processes and identify critical control points.

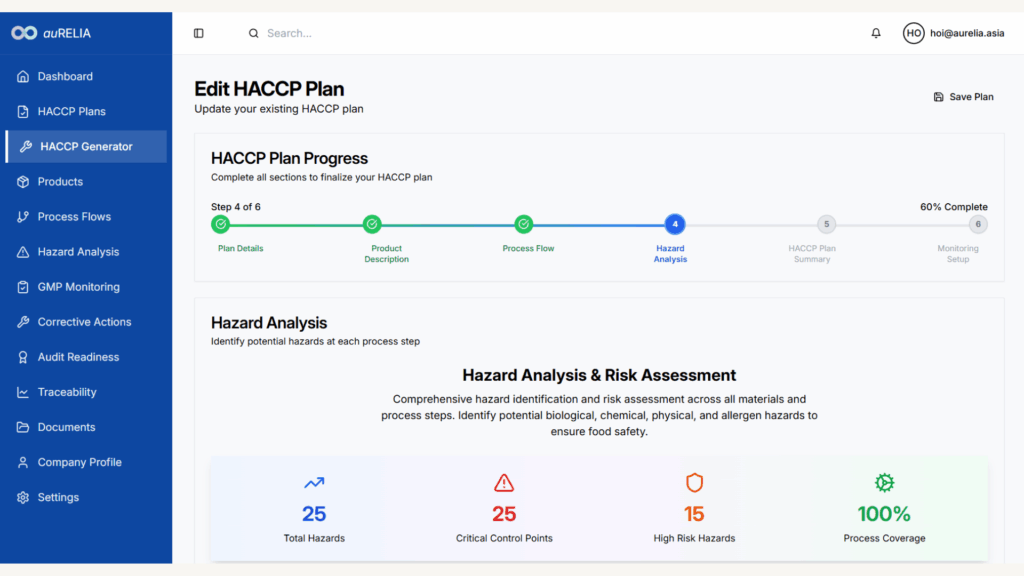

Comprehensive Hazard Analysis Tools

auRELIA’s AI-powered hazard analysis tools proactively identify potential risks before they become compliance problems. The system draws from extensive databases of food safety hazards, manufacturing process risks, and regulatory requirements to ensure no critical risks are overlooked.

Smart HACCP Plan Generation

auRELIA’s MVP 1.0 delivers Smart HACCP Plan Generation that produces comprehensive, tailored HACCP plans aligned with both MS1480 and international Codex standards. Our AI-powered system understands the nuances of Malaysian manufacturing processes and generates documentation that meets the specific requirements of your target export markets.

AI-Generated Custom Process Flow Diagrams

Visual documentation is critical for international compliance audits. auRELIA automatically generates custom process flow diagrams specific to your manufacturing operations, ensuring auditors can quickly understand your processes and identify critical control points.

Comprehensive Hazard Analysis Tools

auRELIA’s AI-powered hazard analysis tools proactively identify potential risks before they become compliance problems. The system draws from extensive databases of food safety hazards, manufacturing process risks, and regulatory requirements to ensure no critical risks are overlooked.

Future-Ready Automation Capabilities

auRELIA’s roadmap extends far beyond current MVP functionality. The platform is designed to deliver up to 70% faster compliance timelines, enhanced audit readiness through intelligent validation systems, and always audit-ready documentation.

Unlike generic software solutions, auRELIA’s platform incorporates deep knowledge of Malaysian regulatory requirements and international compliance standards. The system generates complete HACCP plan summaries in hours rather than weeks, dramatically accelerating your path to market readiness.

The system’s collaborative partnership approach recognises that food safety consultants remain valuable partners in Malaysia’s compliance ecosystem. Rather than replacing consultants, auRELIA streamlines their workflows by pre-generating comprehensive documentation for review and validation, enabling consultants to focus on high-value strategic improvements rather than repetitive documentation tasks.

Transformation: From Compliance Burden to Competitive Advantage

The transformation that auRELIA enables extends far beyond operational efficiency—it fundamentally changes how Malaysian F&B manufacturers approach international market expansion.

Before auRELIA: The Manual Struggle

- 3+ months required for initial HACCP documentation development

- RM50,000+ in consultant fees for comprehensive implementation

- Weeks of internal team time diverted from revenue-generating activities

- Constant anxiety about audit readiness and potential compliance gaps

- Limited scalability that prevents multi-market expansion

- Reactive approach that addresses food safety issues after they occur

This manual approach forces Malaysian manufacturers into a defensive posture—constantly worried about compliance failures rather than confidently pursuing growth opportunities.

After auRELIA: Automated Excellence

- Hours instead of weeks for comprehensive HACCP plan generation

- Significant operational efficiency improvements with up to 70% time savings and reduced human error

- AI-powered hazard analysis that identifies and addresses risks proactively

- Always audit-ready documentation that maintains continuous compliance

- Seamless scalability enabling rapid multi-market expansion

- Enhanced consultant collaboration that maximises professional expertise

The Consultant Collaboration Advantage

auRELIA doesn’t eliminate food safety consultants—it empowers them to deliver higher value. The platform recognises that consultants bring irreplaceable expertise in system optimisation and strategic food safety improvements.

By pre-generating comprehensive HACCP plan summaries, providing AI-powered hazard analysis, and creating prerequisite program templates, auRELIA enables consultants to focus on validation, refinement, and strategic guidance rather than repetitive documentation tasks. This collaborative approach means your consulting investment delivers maximum value while reducing overall project timelines.

Real-time collaboration features enable seamless coordination between your internal team and consultants, ensuring all stakeholders remain aligned throughout the compliance process. Consultants can review, refine, and approve AI-generated documentation efficiently, maintaining their professional oversight while leveraging automation’s speed and consistency.

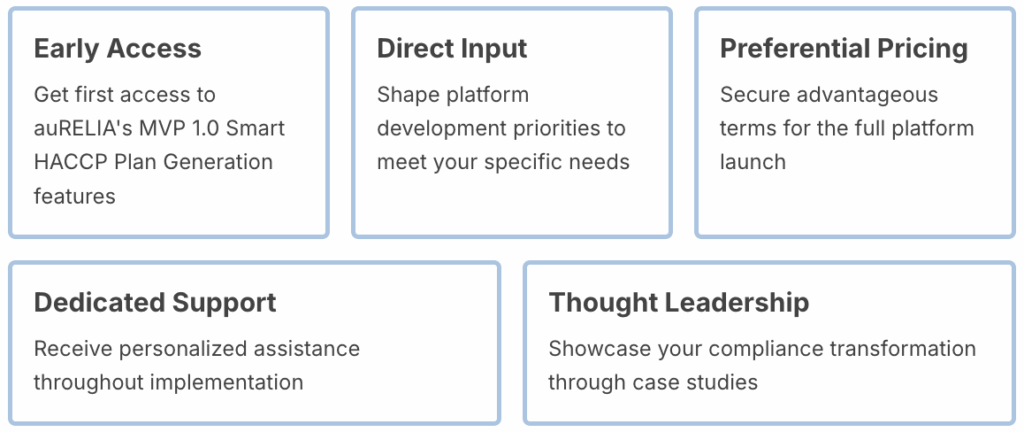

Join auRELIA’s Pilot Program: Be Part of Malaysia’s Compliance Revolution

Malaysian F&B manufacturers have a unique opportunity to lead the industry’s digital transformation. auRELIA’s pilot program offers early access to revolutionary compliance automation technology specifically designed for the Malaysian market.

The pilot program is designed for Malaysian F&B manufacturers ready to embrace the future of compliance automation. We’re specifically seeking companies with 50-500 employees, RM10M-RM100M annual revenue, and active export ambitions.

This is your opportunity to transform compliance from a growth barrier into a competitive advantage while contributing to the development of technology that will define the industry’s future.

Ready to transform your compliance approach?

The path from local to global success is challenging, but with the right tools and support, Malaysian SMEs can overcome compliance barriers and capture their share of the RM31.2 billion processed food export market. auRELIA’s intelligent automation platform, combined with strategic consultant partnerships and comprehensive support programs, provides the foundation for sustainable international expansion.

Don’t let manual HACCP processes hold back your export ambitions. The future of food safety compliance is automated, collaborative, and cost-effective. Join the transformation today.

Schedule a consultation via WhatsApp to discover how auRELIA can accelerate your international expansion while ensuring continuous compliance excellence:

Contact us to schedule a consultation and discover how auRELIA can accelerate your compliance journey while building lasting competitive advantages in international markets.

Connect With Our Founders

Ready to transform your HACCP compliance process? Connect directly with auRELIA’s leadership team:

Ms. Christin Theresa Lim, CEO

Co-founder of auRELIA Insights, specialising in food safety and regulatory compliance for Southeast Asian markets. Her expertise helps businesses navigate complex international standards and ensure seamless market access.

Mr. Arvindran Salyah, COO

Co-founder of auRELIA Insights, bringing extensive experience in market access, financial and operational advisory for agri-business, food and beverage companies. He focuses on sustainable growth and compliance efficiency.

auRELIA Insights is backed by Antler and founded by leaders driving the future of work at the intersection of people and technology. Ready to get export-ready faster? Let’s make compliance work for you—not against you.