Introduction of HACCP

HACCP (Hazard Analysis Critical Control Points) documentation is crucial for Malaysian food manufacturers’ food safety compliance. Essential for competitive international market positioning, streamlined documentation is vital given the industry’s significant 2022 GDP contribution of RM30.5 billion and employment of 234,832 people 1.

Malaysia’s food safety testing market is projected to grow from USD 69.96 million in 2024 to USD 122.01 million by 2032, reflecting increased focus on food safety 2. Malaysian SMEs struggle with HACCP implementation due to high certification costs (RM3,235 – RM4,000), language barriers, and lack of technical knowledge 3 4 5, which could hinder the sector’s full exploitation of Malaysia’s RM35.37 billion processed food export market (2024) 6.

Here are five immediate improvements you can implement to transform your HACCP documentation from a compliance burden into an operational advantage:

1. Streamline Your Hazard Analysis Process

The Challenge:

USDA audits consistently reveal inadequate hazard analysis as a top HACCP deficiency 7 8 9. Food processors often fail to identify all relevant hazards or critical control points, compromising food safety 10.

Quick Win Implementation:

- Break down processes systematically: Hazard analysis requires systematic examination of each processing step separately, as outlined by FDA HACCP and USDA guidelines. Each step, defined as essential to proper production, needs individual evaluation for adequate hazard identification. 11 12 13.

- Use the “Three Types” framework: Hazard analysis identifies biological (bacteria, viruses, parasites), chemical (cleaning agents, sanitisers, allergens), and physical (metal, glass, packaging) food safety hazards at each processing step for comprehensive coverage 14 15.

- Focus on significant hazards: Focus on controlling significant hazards that could cause injury or illness 16. Not all identified hazards need a Critical Control Point (CCP) 17. Evaluate hazards by severity and likelihood to avoid unnecessary CCPs or neglecting high-risk hazards 18. Codex Alimentarius suggests systematic evaluation of hazard occurrence and health impact to determine which hazards require HACCP control 19.

Immediate Impact: According to government studies and academic research, systematic approaches to HACCP hazard analysis can improve efficiency and ensure more comprehensive hazard identification. USDA FSIS data from its HACCP-Based Inspection Models Project demonstrated significant improvements in food safety outcomes 20, while academic research on Malaysian SMEs showed that HACCP implementation led to improved productivity, better resource utilisation, and reduced waste 21.

2. Optimise Critical Control Point (CCP) Selection

The Challenge:

Common audit findings from USDA OIG and FSIS highlight poor CCP identification, with food processors either having too few or too many control points. While model HACCP plans for fully-cooked products include seven CCPs, most audited plants had only one or two, and some had none despite identified hazards 22 23. FDA warning letters also show failures to identify necessary CCPs for critical hazards like allergen control 24.

Quick Win Implementation:

- Apply the CCP Decision Tree systematically: CCP determination uses a decision tree (Figures 2a, 2b) for logical reasoning 25, involving key questions to assess control needs. While similar to Codex, MS1480 requires referring to its specific decision tree for Malaysian compliance 26.

- Distinguish between CCPs and Control Points: Not all control measures are CCPs. Prerequisite programs prevent hazards broadly 27, while CCPs directly control specific, likely hazards 28. For instance, storage temperature monitoring is a prerequisite, whereas cooking temperature is a CCP, directly controlling food safety hazards 29 30.

- Validate your CCP selections: Each Critical Control Point (CCP) must effectively control identified hazards to acceptable levels, as per regulatory definitions 31. If multiple consecutive steps address the same hazard, Codex Alimentarius guidelines state that a later control measure for the same hazard makes the earlier step not a CCP; the subsequent step becomes the CCP. However, if control measures at different steps combine to control the same hazard (e.g., multi-stage heating), both steps are considered CCPs to ensure adequate hazard control 32.

Immediate Impact: Proper CCP selection enables focused monitoring of critical food safety hazards, allowing inspectors to “focus more attention on areas of greatest risk” (USDA) and resulting in “more efficient use of staff” and “reduced waste” (FAO/WHO) 33 3.

3. Create Effective HACCP Monitoring Forms and Procedures

The Challenge:

Poor monitoring and record-keeping are common audit deficiencies, leading to compliance vulnerabilities. USDA audits have shown establishments failing to meet HACCP monitoring and record requirements 35 36. The UK Food Standards Agency confirms that proper HACCP documentation is vital for regulatory compliance and legal protection 37.

Quick Win Implementation:

- Standardise monitoring forms with templates capturing ‘What, How, How often, and Who will monitor.’ Include spaces for quantifiable values, not just checkmarks, as per USDA CFR 417.5(a)(3). Forms must be clear for staff and require signatures/initials as per USDA CFR 417.5(b). 38 39 40

- HACCP verification steps require supervisor sign-offs and equipment calibration records. USDA mandates HACCP plans include “procedures and frequencies for calibration of process-monitoring instruments” to ensure measurement accuracy. Documentation must be signed/initialed by the employee making the entry, and monitoring records must be signed by the person conducting the monitoring and verified by an independent company official. 43 44

- Implement real-time recording of HACCP plan entries to avoid “after-the-fact” documentation, as USDA guidelines confirm that recording results after the monitoring activity constitutes regulatory noncompliance. Position monitoring sheets at workstations. 41 42

Ready-to-Use Templates: Digital monitoring systems, as supported by PMC research, can reduce documentation errors like medication dose and prescription errors common with manual methods, offering real-time alerts and automated monitoring 45.

4. Establish Clear Corrective Action HACCP Protocols

The Challenge:

Inadequate corrective action procedures violate USDA FSIS regulations and FAO HACCP guidelines, risking audit vulnerabilities and regulatory noncompliance. USDA inspection methods deem such failures as grounds for an inadequate HACCP system. Codex standards mandate root cause analysis in corrective actions to prevent recurrence. Government audits frequently cite establishments for deficient corrective actions, leading to regulatory issues and compromised food safety. 46 47 48

Quick Win Implementation:

- Implement step-by-step corrective action protocols for each potential deviation at every Critical Control Point (CCP), as mandated by USDA. These protocols, drawing from the University of Florida Extension and UK Food Standards Agency models, should include: 1) Immediate process control, 2) Deviation and action documentation, 3) Root cause investigation, and 4) Verification of control restoration and recurrence prevention (CFR 417.3(a)). 49 50 51

- Product disposition procedures are crucial for products failing critical limits. USDA mandates that “no product that is injurious to health or otherwise adulterated…enters commerce.” Products are categorised into three dispositions: safe to consume, rework-able, or unsalvageable (requiring disposal). FAO guidelines require documenting product disposition and procedures in HACCP records with proper authorisation. 52 53 54

- Address root causes beyond immediate corrections to prevent recurrence, as mandated by the requirement to establish ‘measures to prevent recurrence.’ A root cause analysis should be conducted where possible to identify and correct the source of the deviation to minimize the possibility of such a deviation occurring again. If temperature deviations occur frequently, investigate underlying causes such as inadequate maintenance standard operating procedures, staff training deficiencies including language barriers, or process design issues that allow deviations to persist. 55 56 57

Immediate Impact: USDA FSIS and FAO HACCP guidelines mandate structured corrective action protocols for audits, detailing deviation response, responsibility, and documentation. While healthcare studies show improved response effectiveness with such procedures, specific quantitative data on HACCP deviation response time reduction is unavailable. Nevertheless, regulatory requirements for predetermined corrective actions promote efficient and consistent responses. 58

5. Implement Smart HACCP Documentation Management

The Challenge:

Poor document control and record-keeping create compliance risks. Common issues include outdated or incomplete documents, and records that are ignored or improperly filled out 59 60. These challenges are especially difficult with complex, multi-line manufacturing processes 61.

Quick Win Implementation:

- Implement clear document identification, authorization, and distribution systems to ensure staff use current procedures. HACCP plans must be signed, dated, and updated upon modification, with proper documentation maintained for regulatory compliance. Poor document control, such as unmanaged or undated documents, is a common compliance issue. Updated procedures should be immediately available at all workstations for consistent implementation and compliance. 62 63

- Organize documentation hierarchically according to the Food Safety Pyramid: HACCP plan at the top, followed by SOPs, prerequisite programs, monitoring forms, and records. This systematic structure (HACCP Manual, flowcharts, plans, procedures, instructions, forms, and records) aids audits and staff training by providing a clear, logical information flow. 64 65

- Annual reassessments of the entire HACCP system are mandatory to identify changes in process steps, processing conditions, and product lines that may introduce new hazards or affect system effectiveness. All reassessments and reasons for changes or no changes must be documented. 66 67

- Retain records for regulatory periods (1 year for refrigerated, 2 years for frozen/shelf-stable) with off-site records available to FSIS within 24 hours. Digital systems are permissible with data integrity controls and backup protocols for electronic records. 6869

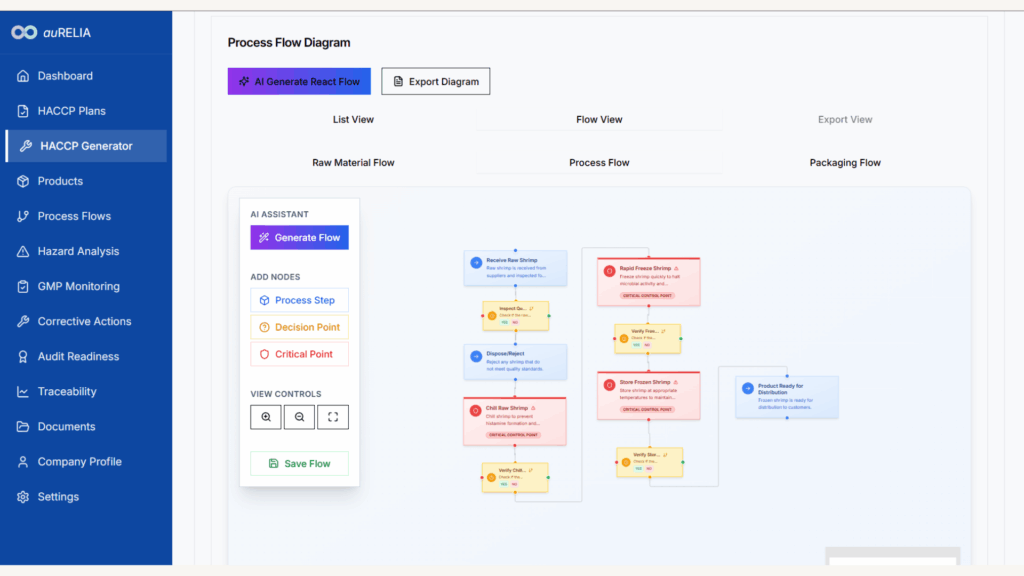

Technology Integration: Digital HACCP systems improve supervision, traceability, and staff efficiency, while cutting administrative overhead by 40-60%. FAO/WHO guidance supports these benefits, highlighting digital tech’s role in enhancing food safety supervision. 70 72 73

Common HACCP Pitfalls to Avoid

- Don’t confuse hazards with causes: Distinguish hazards (e.g. Salmonella) from control measures (e.g. temperature) 74. This affects HACCP plan structure, ensuring proper hazard ID and control measure selection 76.

- Avoid over-documentation by focusing on critical info that demonstrates control effectiveness. HACCP plans should provide ‘necessary procedures and instructions without excessive detail’ 77. ‘Excessive documentation’ creates maintenance burdens that can compromise system effectiveness 78.

- Don’t neglect prerequisite programs: Prerequisite programs can reduce Critical Control Points by controlling hazards before more stringent controls are needed 79 80.

HACCP Implementation Timeline

- Weeks 1-2: Review and optimise hazard analysis using the systematic approach outlined above.

- Weeks 3-4: Evaluate and refine CCP selections using the decision tree methodology.

- Weeks 5-6: Implement standardised monitoring forms and train staff on proper completion.

- Weeks 7-8: Establish corrective action protocols and ensure all staff understand procedures.

- Weeks 9-10: Set up documentation management systems and conduct initial review cycles.

AI-enabled optimisation is crucial. The food industry’s shift to AI-driven process control and stricter regulations makes robust HACCP documentation essential for market competitiveness. In Malaysia, food processors adopting systematic HACCP improvements under MS 1480 consistently report enhanced operational efficiency, reduced waste, and stronger compliance, though gains vary and aren’t universally quantified. 81

Implementing these five quick wins improves compliance and builds an operational foundation for sustainable international growth. With Malaysia’s food imports at RM78.79 billion in 2023 and agriculture-goods exports at RM94.24 billion under MS 1480’s HACCP framework, efficient food safety systems are a competitive differentiator, not just a regulatory requirement. 82 83

Join auRELIA’s HACCP Pilot Program

Ready to transform your HACCP compliance process from weeks to hours? auRELIA’s Smart HACCP Automation platform is designed specifically for Malaysian food manufacturers like you. Our pilot program participants experience up to 70% faster compliance documentation while maintaining full MS1480 alignment.

With our pilot program currently onboarding Malaysian F&B manufacturers, early adopters gain preferential access to platform features specifically designed for full MS1480 alignment.

Connect With Our Founders

Ready to transform your HACCP compliance process? Connect directly with auRELIA’s leadership team:

Ms. Christin Theresa Lim, CEO

Co-founder of auRELIA Insights, specialising in food safety and regulatory compliance for Southeast Asian markets. Her expertise helps businesses navigate complex international standards and ensure seamless market access.

Mr. Arvindran Salyah, COO

Co-founder of auRELIA Insights, bringing extensive experience in market access, financial and operational advisory for agri-business, food and beverage companies. He focuses on sustainable growth and compliance efficiency.

auRELIA Insights is backed by Antler and founded by leaders driving the future of work at the intersection of people and technology. Ready to get export-ready faster? Let’s make compliance work for you—not against you.